I’ve had a couple of Enthusiasts that forwarded me a link from a forum. The discussion centered around the “awkward roof” and why we didn’t lower the side door frames & glass configurations. First let me say that I welcome any constructive criticism or inquiries about the build of this car. The frustrating part is revisiting topics that have been discussed and explained over & over again. I would like to address the question about the side glass and the height as it relates to the windshield. We did not take the “easy way out” and construct something using shortcuts. Many of the “suggestions” that people have provided were considered LONG before they were made by the critics. We thought many of the same things until we become involved in the engineering and physics of the project. I learned that sitting in a chair verbalizing the “obvious” was nothing like building and engineering the real thing. While the light blue/gray Artist’s rendering of the 4 Door Barracuda looks appealing, that appearance would never work in actual design. It’s like painting a nice looking humanistic Robot where the internals are not shown or functionally illustrate the actual creation. It’s a just a fictitious painting that represents a hypothetical idea. (The back glass would never roll down into the door frame that is shown in the painting of the 4 Door Barracuda.)

I would like to once again explain the engineering process of our design and why we built what we built. From the start, we realized that we had to work with what was available. Even with the parts that we had access to, there was a tremendous amount of fabrication and alterations to make those components work. First, we had to engineer a realistic design for the cowl, dash frame, windshield, A pillar and door frames, in order for them to work in unison. Since a B Body windshield would not work with the cowl frame of a Barracuda, the windshield frame of a Barracuda had to be morphed with a B Body roof and A pillar. The inner half of the A pillar on this car is a 1970 Barracuda design (for the proper fitment of the windshield with the cowl) and the outer half is a B Body A pillar design. The A pillar tapers towards the Cowl because the outer section still has to line up and door seal of the B Body door frames. It is IMPOSSIBLE to lower/shorten the door frames and still use the stock configuration of the B Body glass. Many have suggested that we perform that type of alteration but they do not understand the physics of what they’re suggesting. If you cut and alter the door frames to lower them by 2 inches, the front edge of the frames will have to be moved 2 inches back from the cowl. That would leave an 2 inch gap from the front of the door frame to the area that seals against the A Pillar. It will not work. The roof would also have to be cut apart in 4 sections and widened to accommodate the door frames being shortened and lowered. That would cause a domino effect of design changes with the cowl width, the dash width, the headliner width, the vinyl top width, the window regulators, the door seals, the weatherstripping, and the glass. Many of you have no idea the changes that would need to be made from simply removing a couple of inches out of the door frames. It sure is easy to write about in a sentence or two but extremely difficult to apply in a real world build.

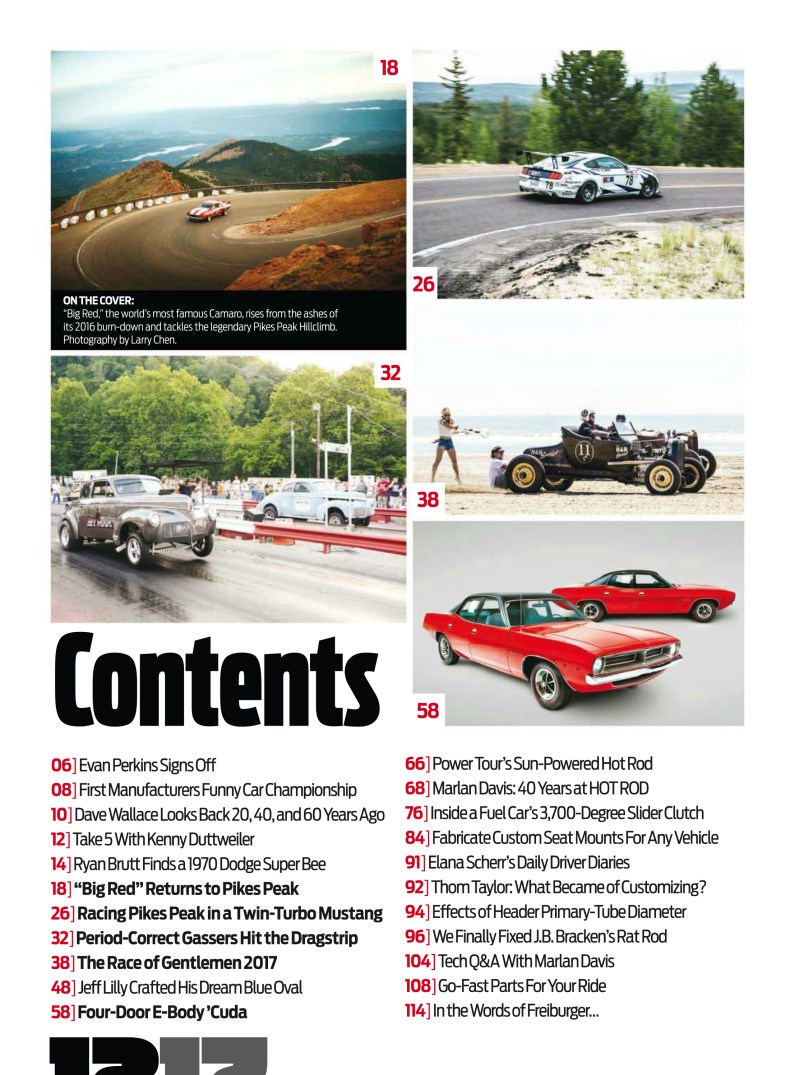

Some of you don’t like the design because it’s different and you’re not use to seeing it. Had the car been offered in 1970, there may not have been so many negative comments that are made today. Having the real 2 door Barracuda makes it that much easier to criticize this 4 door design because we are use to seeing the actual Factory version. There were many cars built that have “odd” appearances but they are accepted because they are “real” cars. No one has to like ALL the different variations and designs. That’s why the Manufacturers made so many different makes & models. I know this car is polarizing and unappealing to some people. That’s fine and can be expected with a project like this. One thing I can assure the critics is that ALL of your suggestions and solutions were considered by us LONG before you ever thought about them. I have an Engineering background I can assure those “critics” that many of you would have given up had you been faced with the complexity of this project. You remind me of those who stand at the bottom of Mount Everest and ask those descending from the top, “What’s the big deal? All you had to do was walk up the side of that Mountain and then walk back down!” I guess it’s true that those who complain from the sidelines, typically think they’re more accomplished than those who actually master the Game.